Clutch Upgrades and why we need them!

11th Jul 2025

In very basic terms, the vehicle clutch allows you to disconnect the engine and gearbox temporarily when changing gear or of course, setting off from standstill etc when pressing the clutch pedal.

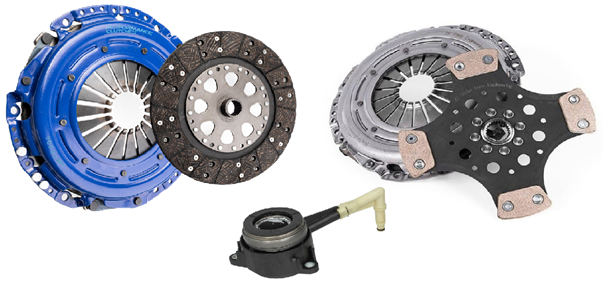

There are four key components to a clutch kit.

Clutch disc (Drive Plate)

Pressure Plate

CSC (concentric slave cylinder) or release bearing

The pressure and drive plates are then bolted directly to the “Flywheel”

There are other components that assist the engagement and disengagement; from the pedal, to master cylinder, slave cylinder bleeder blocks and fluid lines.

Drive Plate: A disc with friction material, this is connected (sandwiched between) to the flywheel and pressure plate

Pressure Plate: Holds the drive plate against the flywheel allowing its friction material to transmit the power/torque to the drivetrain of the vehicle and ultimately to the road.

CSC (Slave cylinder and/or bearing): This is activated when pressing the clutch pedal, forcing the pressure plate away from the flywheel and thus stopping the transmitting of power/torque momentarily.

So, your car already has a clutch, why would you need to “upgrade”?

A “standard” or OE clutch with withstand a certain amount of torque before you experience clutch slip (when the drive plate and pressure plate no longer prevent the engine disengaging momentarily or partially.)

At Awesome we currently have two Clutch manufacturers available for you. We supply Sachs Performance (ZF) and Performance clutches.

What will you gain and are there any differences from the OE (Standard) clutch in terms of how the feel or how the car can perform?

As we tune our vehicles (re-map etc) we increase the amount of power and torque the engine produces, in this blog we will mainly focus on torque.

As we increase the amount of torque the standard clutch drive and pressure plates are less likely to cope and inevitably the clutch will slip or in some case fail completely.

So how do the clutch upgrades we supply, handle this increased torque better?

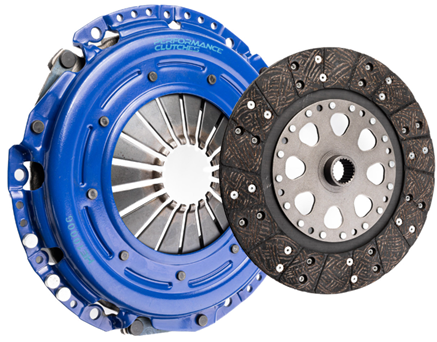

We offer largely, 2 different types of clutches, a Road friendly version, and one focused more towards high torque and track type applications.

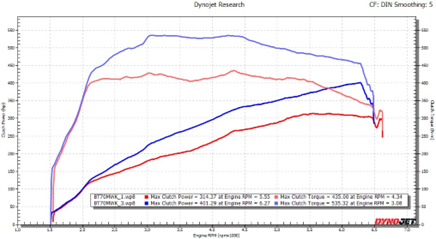

The Fast Road clutches are commonly referred to as “Organic” (Carbon and metal woven fibres in phenolic resins) due to the friction material used on the Drive plate. Together with a performance pressure plate providing increase clamping force, these clutches can hold around 400-420lb ft of torque (542-569nm), whilst still operating in a very similar fashion to the original clutch. Great for everyday use and “spirited” A and B road driving.

The Track focused clutches such as the Sachs Performance Sintered paddle clutches can cope with around 550lbft (746nm) of torque but will be more of a “on-off” style clutch as the clutch drive plate is no-longer a full circle of friction material but that of a number of “pucks” or “paddles” 4, 5 or six paddles can be expected. The “sintered” material is formed under heat and pressure and can withstand more in the way of force. These clutches are ideal for track vehicles, high rev downshifting and applications where the clutch must work much harder.

The trade off with this style of clutch is the very heavy pedal and can be difficult to live with in heavy traffic etc.

Uprated clutch pressure plates as mentioned, provide increased clamping force, with this comes a “heavier” clutch pedal but very often we get used to that.

Some VAG applications such as the EA888.3 engined Golfs, Audis, Skodas, and Seats, require a clutch upgrade as soon as they have any increased power and torque introduced (Stage 1), as the OE clutch simply is at its limit with standard power and torque. We have package deals with Software, clutch and fitting available which will also save you money over buying these items separately.

Flywheels:

We can supply either Dual mass flywheels (DMF) or Single mass flywheel conversions (SMF).

The factory flywheel in modern vehicles tend to be a Dual Mass. (DMF)

A DMF works with two flywheels connected with springs to allow independent movement, absorbing vibrations caused be the engine, the OE manufacturer prefers this over SMF versions as it allows a smoother drive for the driver. A single Mass (SMF) conversion (one piece of iron or steel) will be cheaper but will not absorb these vibrations and be much less refined. Again, for track applications this may not be an issue.

We recommend changing the Flywheel with any clutch upgrade as they often fail, it’s a time consuming and sometime costly job to do twice and can affect the warranty of the clutch if not replaced. A failing flywheel can cause damage and the clutch to slip.

Visit our website to see whats on offer www.awesomegti.com

Call our Bookings team if you would like us to supply and fit 0161 776 0777 opt1 or bookings@awesomegti.com